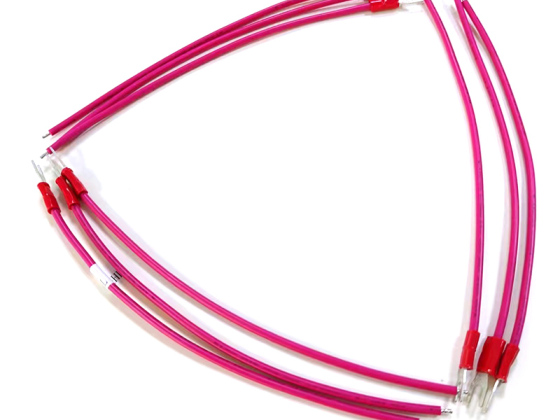

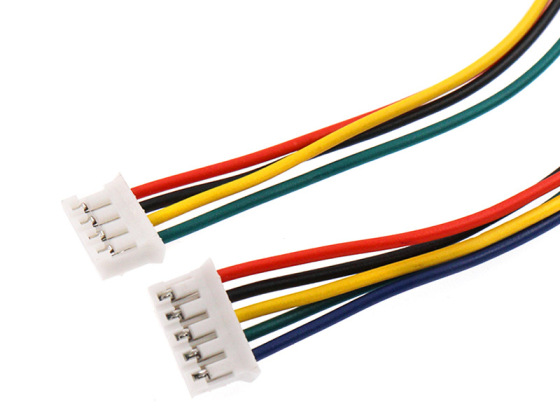

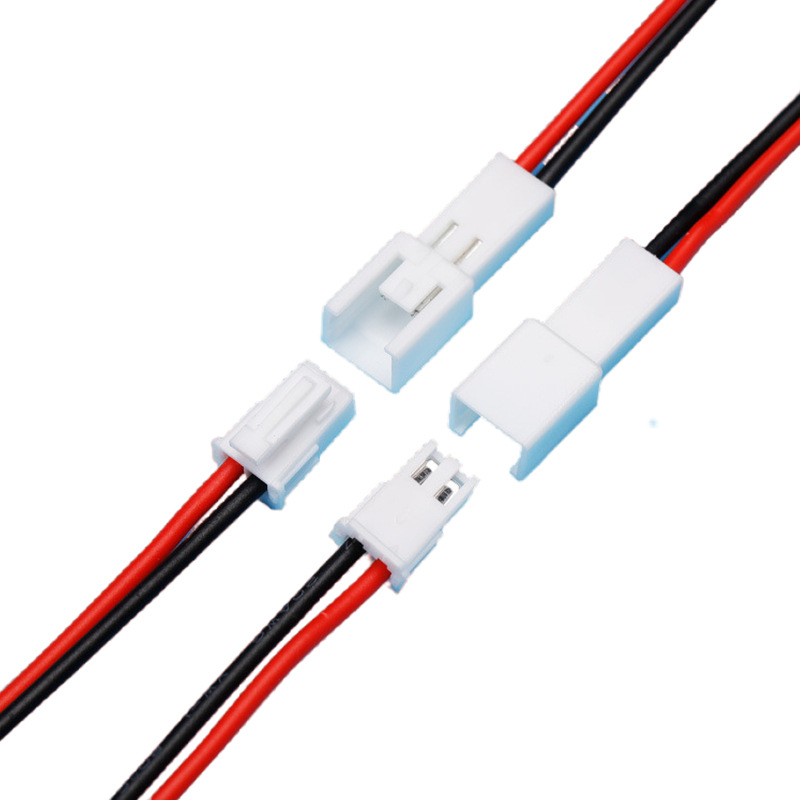

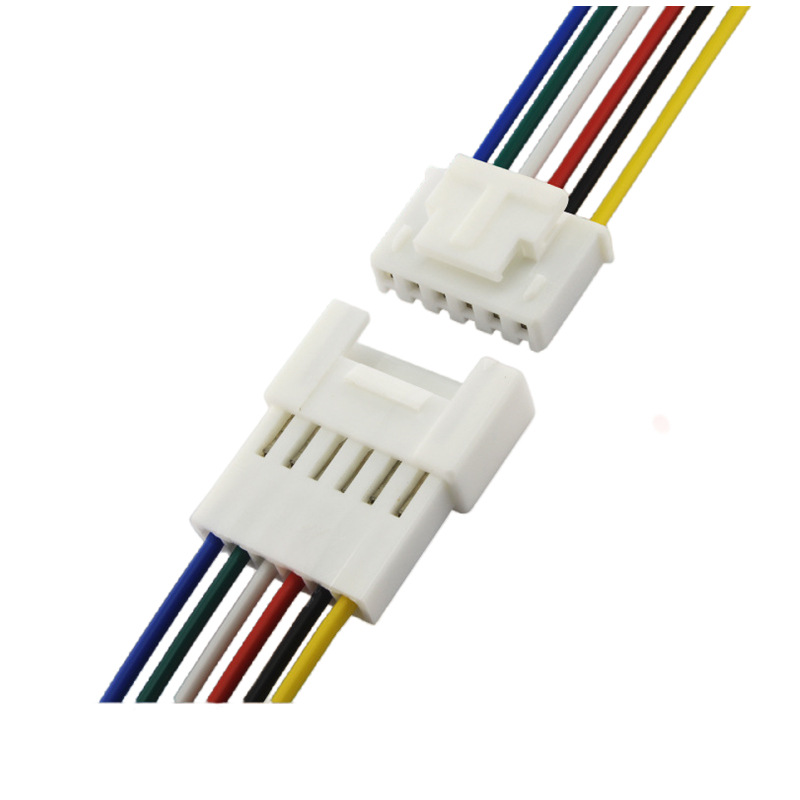

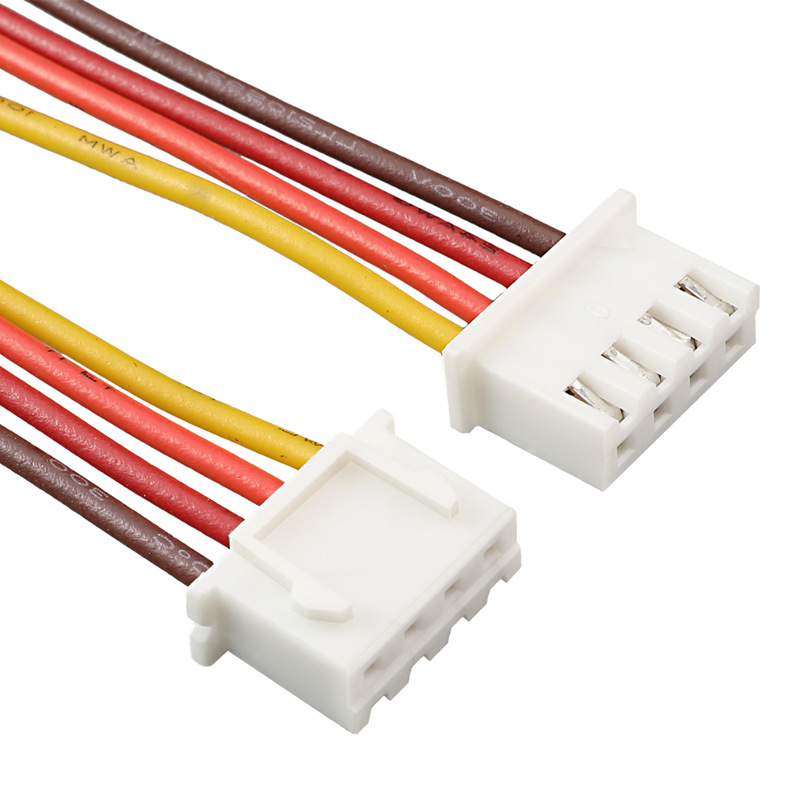

Cablaggio di prolunga con connettore maschio e femmina SM2.5

Cablaggio e assemblaggio cavi personalizzati in fabbrica, cablaggio con connettore M2,5 mm di alta qualità, cablaggio maschio-femmina, cablaggio con connettore 2-1 pin. Prezzo di fabbrica per tutti i tipi di apparecchiature.

Il prodotto è applicabile principalmente a computer, comunicazioni elettroniche, strumenti, contatori, programmi di controllo industriale, DVD, schermi LCM/LCD, giochi elettronici e fornisce connessioni affidabili tra cavi scheda-scheda.

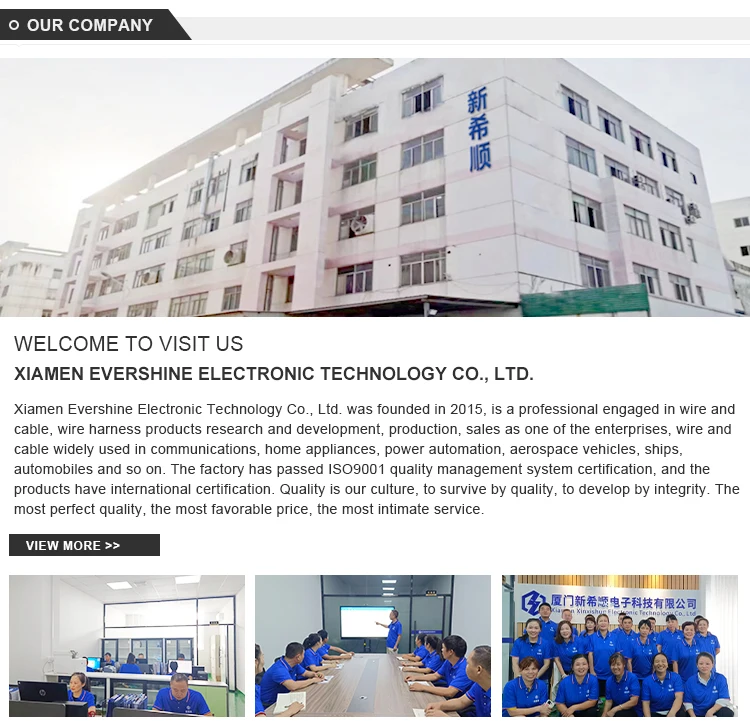

- Evershine

- Xiamen

- 7~15 giorni

- 100000 pezzi/mese

- informazione

Product spacing: 2.5mm

Product wire specifications: UL 1007 28awg

Product color: customized (red,black,white)

Product length: Customized

Product specifications: 2-12pin wires

Product outer diameter: 1.3mm

Q1:How can I get your quotation?

A1: In order to provide an accurate quotation, we may need additional information such as drawing, samples, or specific customization requests. Please provide any relevant information or documentation to help us understand your needs. Our sales team will review your requirements and prepare a quotation based on the provided information. This quotation will include details such as the price, payment terms, lead time, and any other relevant terms and conditions.Q2:Do you support free sample for testing?

A2:Yes, we offer support for free samples for testing purposes. We understand the importance of evaluating a product before making a purchase decision. However, please note that while the samples themselves are free, you may be responsible for covering the shipping and handling costs. Our sales team can provide more information on the specific terms and conditions for obtaining free samples. Q3:How you control the quality?A3:We have implemented a comprehensive quality control system to ensure the highest quality standards in our products, including raw material inspection, In-process quality checks, testing and validation, quality assurance team, and continuous improvement

Q4:How you guarantee your lead time?

A4: By effective production planning and supply chain management, Monitoring and tracking orders ( own Unit Manager System that control material and making times) , and open communication and transparency with customers., we strive to consistently deliver products within the agreed-up on lead time and meet our customers' expectations. Q5:How you keep your competitive price?A5: we have implemented several strategies. One of these strategies is the incorporation of automated machinery and processes into our operations. By utilizing automation, we are able to streamline production, increase efficiency, and reduce labor costs. This, in turn, allows us to offer more competitive pricing to our customers without compromising on quality. Additionally, automation helps us minimize errors and improve consistency, further enhancing the value we provide to our customers.

these are some of the things people often ask about:

1. What is an Extension Wire Harness?

An extension wire harness is a pre-assembled set of wires and connectors designed to extend the reach of existing electrical connections within a system. It essentially acts as an electrical dddhhhextension cord,dddhhh allowing you to connect components that are physically further apart than the original wiring allows. They are used across various industries to simplify modifications, expansions, and repairs of electrical systems. They often include protective sheathing and secure connectors to ensure reliable and safe operation.

2. Common Applications of Extension Wire Harnesses

Extension wire harnesses are commonly used in automotive applications to connect trailer lights, in industrial machinery to extend sensor connections, and in consumer electronics to adapt peripherals. They are also prevalent in RVs and boats for expanding electrical systems and in custom computer builds for routing power and data cables. Their versatility makes them essential for any situation where existing wiring is insufficient in length.

3. Materials Used in Extension Wire Harnesses

Typical materials include copper wires for optimal conductivity, PVC or polyethylene insulation for protection against shorts and environmental factors, and durable plastic or metal connectors for secure and reliable connections. The gauge of the wire is selected based on the current it needs to carry. High-quality materials ensure longevity and prevent failures, especially in demanding environments.

4. Benefits of Using Extension Wire Harnesses

Extension wire harnesses offer several advantages, including simplified installation, reduced risk of wiring errors, and improved system organization. They eliminate the need for cutting and splicing existing wires, preserving the integrity of the original wiring. This leads to increased reliability, easier troubleshooting, and faster modifications or repairs, saving time and costs.

5. Safety Considerations When Using Extension Wire Harnesses

When using extension wire harnesses, it’s crucial to match the wire gauge to the current requirements to prevent overheating and fire hazards. Ensure connectors are properly secured to avoid loose connections and electrical arcing. Protect the harness from physical damage and environmental exposure. Regularly inspect for wear and tear, and replace damaged harnesses immediately to maintain safety and reliability.

6. Customization Options for Extension Wire Harnesses

Extension wire harnesses can be customized in various ways, including cable length, wire gauge, connector type, and shielding. Customization allows for precise matching to specific application requirements, ensuring optimal performance and integration. Options like labeling and color-coding further simplify installation and maintenance, minimizing the risk of errors.

7. How to Choose the Right Extension Wire Harness

Selecting the right extension wire harness involves considering factors like voltage and current requirements, environmental conditions, connector compatibility, and cable length. Verify that the harness meets relevant industry standards and safety certifications. Always opt for high-quality materials and connectors to ensure long-term reliability and prevent costly failures.

8. Common Problems with Extension Wire Harnesses

Common problems include loose connections, corroded contacts, damaged insulation, and overloaded circuits. These issues can lead to intermittent failures, signal loss, and potential safety hazards. Regular inspections and proper maintenance are essential for preventing these problems. Replacing damaged or worn-out harnesses promptly is crucial for maintaining system reliability.

9. Installation Tips for Extension Wire Harnesses

Before installation, disconnect power to the system. Carefully route the harness to avoid sharp bends and contact with moving parts or hot surfaces. Secure connectors firmly and ensure proper grounding. Use cable ties or clips to keep the harness organized and protected. After installation, test the connections to verify correct operation.

10. Future Trends in Extension Wire Harness Technology

Future trends include the use of lighter and more durable materials, integration of smart sensors for diagnostics, and wireless connectivity options. Modular designs will allow for easier customization and upgrades. Advances in manufacturing automation will lead to more cost-effective and reliable extension wire harnesses that meet the evolving needs of various industries.